Why you must check the Viscosity of Gear Oil

Picking the right gear oil can be a daunting endeavour given the numerous products on the market. The viscosity is one criterion to prioritise when buying a lubricant. Some machines have a qualified product list that indicates the viscosity grade suitable for the particular gear sets. Why does it matter though how viscous a lubricant is?

Classifications of Viscosity

Viscosity refers to the internal resistance that gear oil has to flow. An increase in temperature decreases viscosity, meaning that the lubricant thins while lower temperatures cause an increase in viscosity. Manufacturers indicate the viscosity of a lubricant on the label because it is the biggest determinant of oil suitability. SAE (Society of Automotive Engineers) is responsible for setting viscosity standards. SAE J306 is used to categorise axle and manual transmission lubricants while SAE J300 is for engine oils. Gear oil is then categorised according to grade like low temperature (winter).

The role of Viscosity in Gear Oil

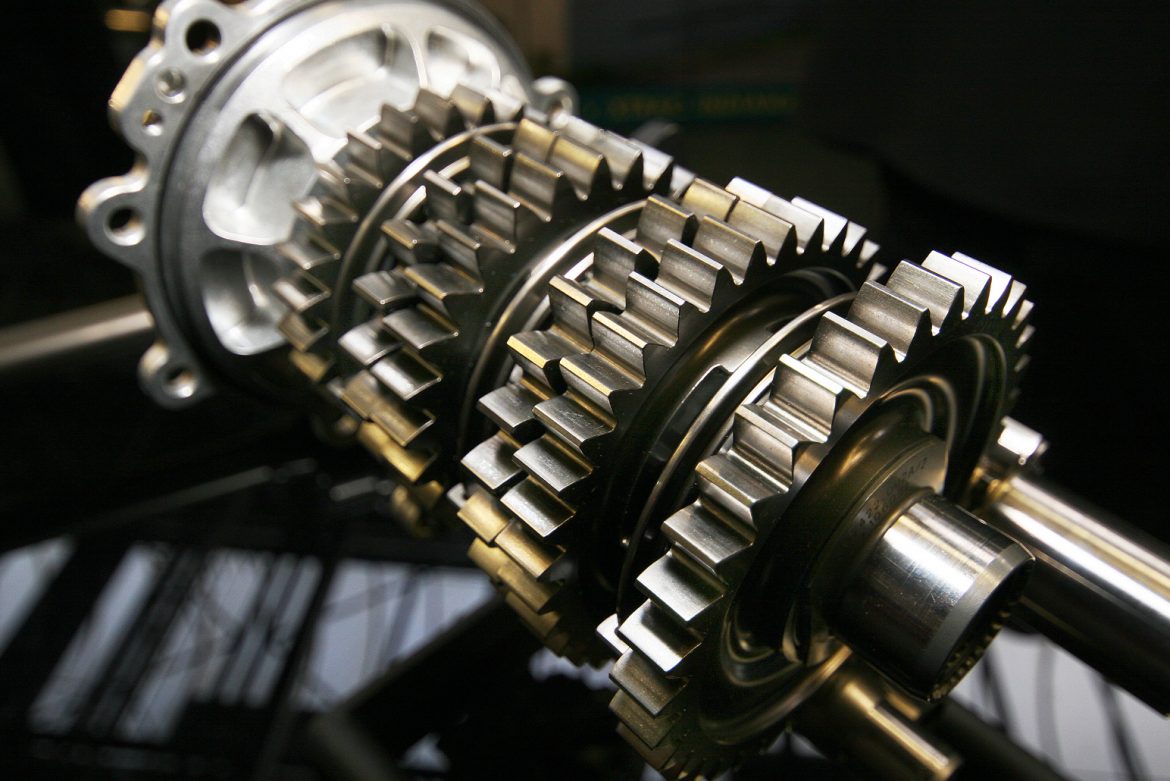

The resistance to flow in a lubricant will influence heat generation in bearings, gears and cylinders. Consequently, it impacts the performance of these components. Viscosity is used to provide a film between surfaces and, therefore, the grade will determine the thickness of this film. Temperature and load will also affect the effectiveness of lubrication. Gear oil can be used as a seal when lubricating parts. However, this ability depends on how viscous the lubricant is. The viscosity grade facilitates the operation of gear sets in different temperatures. The adequate grade will allow a machine to start at low temperatures and keep running when reached high temperatures.

The rate of wear and tear in a machine will depend on the viscosity of the gear oil used for maintenance, hence the need to get the right grade.